Søgeresultat

The FLIR GF77 is a groundbreaking uncooled optical gas imaging camera with interchangeable lens options that detect methane (CH4), sulfur hexafluoride (SF6), ethylene (C2H4), ammonia (NH3), and other gas emissions. Capable of both gas detection and radiometric temperature measurement, the GF77 is an ideal inspection tool for electric power utilities, oil and natural gas operations, chemical/manufacturing facilities, the food and agriculture industry, and first responders. This camera offers unmatched versatility as well as improved visualization of gas emissions and thermal inspections.

Based on the award-winning design of the FLIR T-Series platform, the GF77 offers a vibrant, 4-inch touchscreen LCD, 180° rotating optical block, and eyepiece for convenience in direct sunlight. This affordable solution offers the benefit of built-in thermographic calibrations and the flexibility to detect a wide range of gases by

simply changing lenses.

- Scan for gas emissions and follow them to the source so you can begin repairs immediately

- Visualize gases in specified spectrum while also reducing false negatives of gases that absorb in another wavelength

- See gases easier and make decisions quickly thanks to vibrant 4” LCD display

- Switch to viewfinder in bright, sunlit conditions to ensure optimal viewing

- Improve image contrast with 1-Touch Level/Span auto-adjustment feature

- Increase leak detectability by activating FLIR’s patented High Sensitivity Mode (HSM)

- Precisely resolve target area with laser-assisted autofocus

- Use comfortably—long-term—with award-winning ergonomic design, including 180° rotating lens

- Connect instantly over Wi-Fi to mobile devices for data transfer and reporting

FLIR GF77 Gasskamera 25° LR (7-8.5 µm)

EAN 7332558023112

EL-NR 6398741570

RING FOR PRIS +45 7022 1000

The FLIR GF77 is a groundbreaking uncooled optical gas imaging camera with interchangeable lens options that detect methane (CH4), sulfur hexafluoride (SF6), ethylene (C2H4), ammonia (NH3), and other gas emissions. Capable of both gas detection and radiometric temperature measurement, the GF77 is an ideal inspection tool for electric power utilities, oil and natural gas operations, chemical/manufacturing facilities, the food and agriculture industry, and first responders. This camera offers unmatched versatility as well as improved visualization of gas emissions and thermal inspections.

Based on the award-winning design of the FLIR T-Series platform, the GF77 offers a vibrant, 4-inch touchscreen LCD, 180° rotating optical block, and eyepiece for convenience in direct sunlight. This affordable solution offers the benefit of built-in thermographic calibrations and the flexibility to detect a wide range of gases by

simply changing lenses.

- Scan for gas emissions and follow them to the source so you can begin repairs immediately

- Visualize gases in specified spectrum while also reducing false negatives of gases that absorb in another wavelength

- See gases easier and make decisions quickly thanks to vibrant 4” LCD display

- Switch to viewfinder in bright, sunlit conditions to ensure optimal viewing

- Improve image contrast with 1-Touch Level/Span auto-adjustment feature

- Increase leak detectability by activating FLIR’s patented High Sensitivity Mode (HSM)

- Precisely resolve target area with laser-assisted autofocus

- Use comfortably—long-term—with award-winning ergonomic design, including 180° rotating lens

- Connect instantly over Wi-Fi to mobile devices for data transfer and reporting

FLIR GF77 Gasskamera 25° HR (9.5-12 µm)

EAN 7332558027134

RING FOR PRIS +45 7022 1000

Batteri FLIR T8xx/T5xx/GF77

EAN 4743254003378

EL-NR 6398741457

På lager Lav lagerbeholdning Snart på lager igen

1.485,00 DKK Excl. moms

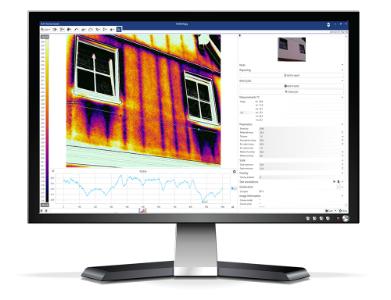

FLIR Thermal Studio er en kraftfuld, fleksibel og effektiv software til analyse og oprettelse af termiske inspektionsrapporter. I Softwaren kan de termiske billeder editeres/ optimeres, og Thermal Studio kan håndtere brugerdefinerede skabeloner samt rapporter med mange termiske billeder uden der opstår problemer med hastigheden i programmet. Softwaren supporterer stillbilleder og video i standard FLIR format, fra alle moderne termiske FLIR kameraer inklusiv C-, T-, E-, og GF-serien samt FLIR One og P6-serien.

FLIR Thermal Studio er tilgængelig i over 20 forskellige sprog (og selvfølgelig også dansk). Softwaren er et "stand-alone program", som er kompatibelt med Windows 7, 8, 10 i 32- og 64-bit versioner (kræver ikke Microsoft Office til rapportgenerering),

FLIR Thermal Studio Standard, 1 års abonnement P/N T300341

EAN 7332558026779

På lager Lav lagerbeholdning Snart på lager igen

1.755,00 DKK Excl. moms

Batteri FLIR P600/B600 og GF serien T199183ACC

EAN 5706445880515

EL-NR 6398741224

På lager Lav lagerbeholdning Snart på lager igen

1.975,00 DKK Excl. moms

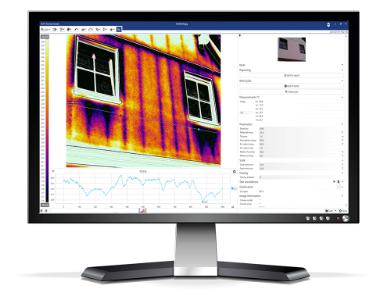

FLIR Thermal Studio er en kraftfuld, fleksibel og effektiv software til analyse og oprettelse af termiske inspektionsrapporter. I Softwaren kan de termiske billeder editeres/ optimeres, og Thermal Studio kan håndtere brugerdefinerede skabeloner samt rapporter med mange termiske billeder uden der opstår problemer med hastigheden i programmet. Softwaren supporterer stillbilleder og video i standard FLIR format, fra alle moderne termiske FLIR kameraer inklusiv C-, T-, E-, og GF-serien samt FLIR One og P6-serien.

FLIR Thermal Studio er tilgængelig i over 20 forskellige sprog (og selvfølgelig også dansk). Softwaren er et "stand-alone program", som er kompatibelt med Windows 7, 8, 10 i 32- og 64-bit versioner (kræver ikke Microsoft Office til rapportgenerering),

FLIR Thermal Studio Pro, 1 års abonnement P/N T300243

EAN 7332558025727

På lager Lav lagerbeholdning Snart på lager igen

3.515,00 DKK Excl. moms

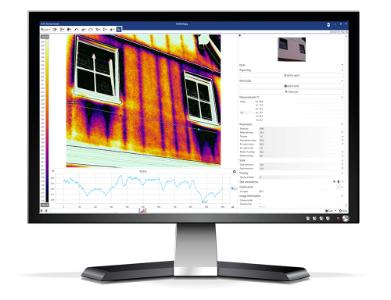

FLIR Thermal Studio er en kraftfuld, fleksibel og effektiv software til analyse og oprettelse af termiske inspektionsrapporter. I Softwaren kan de termiske billeder editeres/ optimeres, og Thermal Studio kan håndtere brugerdefinerede skabeloner samt rapporter med mange termiske billeder uden der opstår problemer med hastigheden i programmet. Softwaren supporterer stillbilleder og video i standard FLIR format, fra alle moderne termiske FLIR kameraer inklusiv C-, T-, E-, og GF-serien samt FLIR One og P6-serien.

FLIR Thermal Studio er tilgængelig i over 20 forskellige sprog (og selvfølgelig også dansk). Softwaren er et "stand-alone program", som er kompatibelt med Windows 7, 8, 10 i 32- og 64-bit versioner (kræver ikke Microsoft Office til rapportgenerering),

FLIR Thermal Studio Standard, evig licens P/N T300258

EAN 7332558025734

RING FOR PRIS +45 7022 1000

FLIR Thermal Studio er en kraftfuld, fleksibel og effektiv software til analyse og oprettelse af termiske inspektionsrapporter. I Softwaren kan de termiske billeder editeres/ optimeres, og Thermal Studio kan håndtere brugerdefinerede skabeloner samt rapporter med mange termiske billeder uden der opstår problemer med hastigheden i programmet. Softwaren supporterer stillbilleder og video i standard FLIR format, fra alle moderne termiske FLIR kameraer inklusiv C-, T-, E-, og GF-serien samt FLIR One og P6-serien.

FLIR Thermal Studio er tilgængelig i over 20 forskellige sprog (og selvfølgelig også dansk). Softwaren er et "stand-alone program", som er kompatibelt med Windows 7, 8, 10 i 32- og 64-bit versioner (kræver ikke Microsoft Office til rapportgenerering),

FLIR Thermal Studio Pro, evig licens P/N T300083

EAN 7332558023570

EL-NR 6398741651

RING FOR PRIS +45 7022 1000